The history of 3D printing can be traced back to the early 1980s when Chuck Hull invented stereolithography (SLA) – one of the first additive manufacturing processes. In 1984, Hull founded 3D Systems Corporation, which is now one of the world’s leading manufacturers of 3D printers.

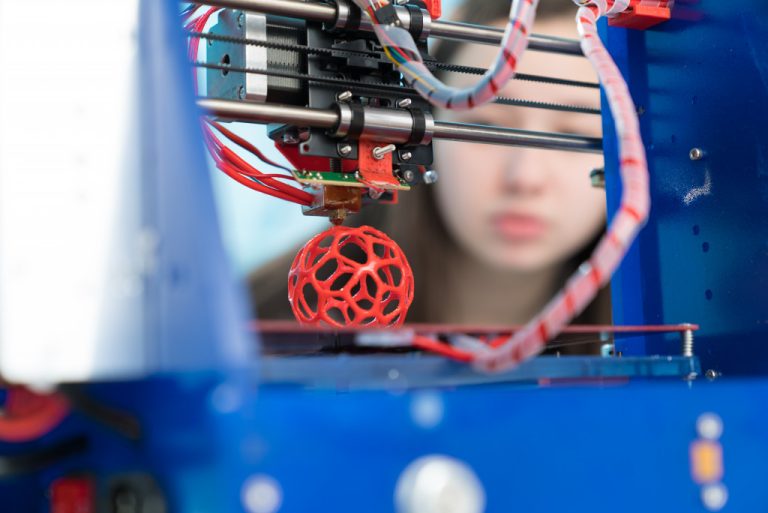

Since then, 3D printing technology has come a long way. Today, there are many 3D printing technologies and materials available, from plastics and metals to ceramics and food. And as technology continues to evolve, the possibilities for what can be created with a 3D printer are endless.

One of the most exciting applications of 3D printing is in businesses. Here are five ways your business can take advantage of 3D printing technology:

Rapid prototyping

Rapid prototyping is defined as “the construction of a three-dimensional object from a computer-aided design model, usually within a day or less.”

In the past, businesses would have to outsource the creation of prototypes, which would often take weeks or even months. But with 3D printing, companies can create prototypes in-house quickly and easily. This saves time and money and allows businesses to be more agile and responsive to change.

There are many advantages to rapid prototyping. One is that businesses can test out multiple design iterations quickly and cheaply. This is especially important in today’s rapidly changing business environment, where the ability to pivot quickly is essential for success.

Another advantage of rapid prototyping is that it allows businesses to create customized products. With 3D printing, companies can develop products specifically tailored to their customers’ needs and wants. This level of customization was simply not possible before 3D printing.

Customization

As mentioned before, one of the significant advantages of 3D printing is that businesses can create customized and personalized products. This is made possible because 3D printers can create objects with very intricate designs.

This level of customization and personalization is great for businesses, but it’s also great for customers. Customers today are increasingly demanding products tailored to their specific needs and want. And with 3D printing, businesses can now meet this demand.

Some examples of businesses already taking advantage of this trend include eyewear company Warby Parker and jewelry company BaubleBar. Warby Parker uses 3D printing to create custom-fit eyeglasses for its customers. And Ba

On-demand manufacturing

Another way businesses can take advantage of 3D printing is through on-demand manufacturing. This refers to the ability to produce products only when needed, which eliminates the need for inventory storage.

This is made possible because 3D printers do not require traditional manufacturing processes such as molding and casting. As a result, businesses can produce products much faster and less lead time.

This is especially beneficial for businesses that have seasonal products or need to be responsive to sudden changes in demand. For example, if a company suddenly experiences an increase in demand for a particular product, it can quickly ramp up production using 3D printing without worrying about excess inventory.

Inventory management is a crucial part of any business, but it can be difficult and costly. With on-demand manufacturing, companies can streamline their inventory management process and save both time and money.

Lower costs

One of the significant advantages of 3D printing is that it can help businesses lower their production costs. This is because 3D printing eliminates the need for traditional manufacturing processes, which often require expensive equipment and materials.

In addition, 3D printing also allows businesses to produce products in small batches. This is especially beneficial for businesses that are just starting or that are testing new product ideas.

With lower production costs, businesses can invest more in research and development, leading to even more innovation.

3d printing is pretty great for any modern businesses out there, but there are also some alternatives that exist that can do the same things that a 3d printer can do.

Laser Cutting

Laser cutting is another technology that can be used for rapid prototyping and on-demand manufacturing. Like 3D printing, laser cutting is a digital fabrication technology that allows businesses to quickly and easily create prototypes and products.

However, there are some key differences between laser cutting and 3D printing. One of the main differences is that laser cutting generally works best with flat materials, while 3D printing can work with both flat and three-dimensional materials.

Another difference is that laser cutting is typically faster than 3D printing. This is because laser cutters can cut through material very quickly. However, this also means that laser cutting is generally more expensive than 3D printing. Despite this, you can still make decent money with a laser engraver. In some situations, it might even be cheaper.

3D printing is an excellent way for businesses to create custom products, lower production costs, and streamline inventory management. However, there are some alternative technologies that can also be used for these purposes. Businesses should consider all of their options before deciding which technology is best for them.